Product

Suspended field sprayer 300 L

Specification

Suspended field sprayer P166 300 L

Standard equipment:

- Main tank 300 L

- Hand wash tank

- Top inducer – in the infusion

- Manually unfolding beam

- Boom Lifting – Hand Winch

- Single VK luminaire

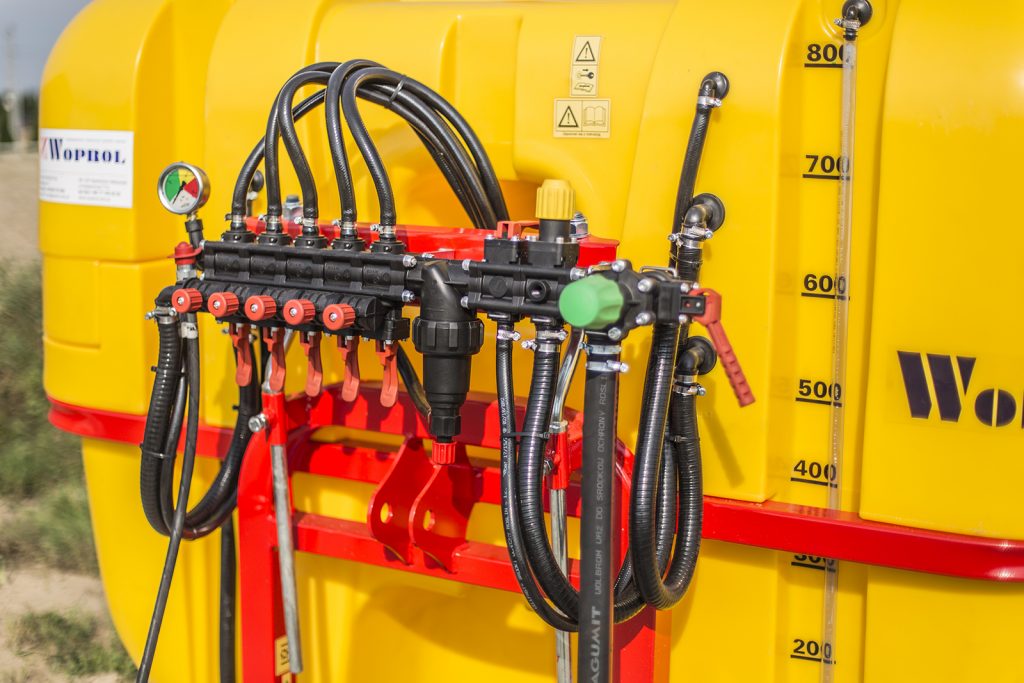

- 4 section control valve (diverter)

Additional options

- Hydraulic boom lift

- Hydraulic or mechanical stabilization

- ARAG 5-section constant pressure valve

- 3-position fittings with a set of nozzles

- Hose with suction strainer for filling the tank

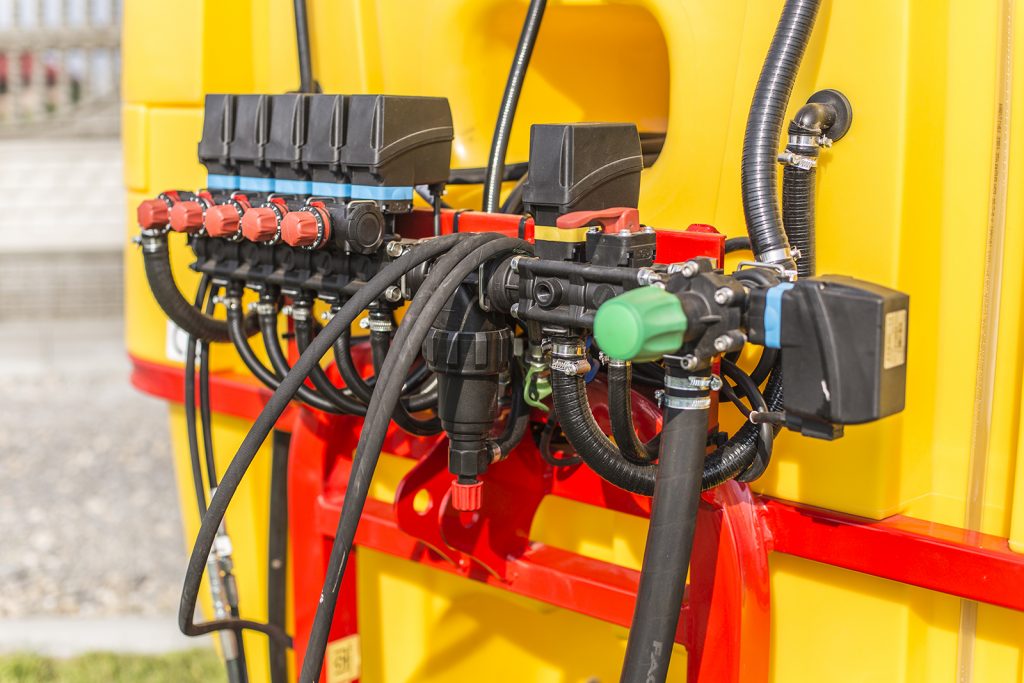

- Open / close electrical panel (for ARAG constant pressure valve)

- Electric valve control from the tractor

- ARAG Bravo 180S / 300S / 400S computer (with built-in GPS navigation)

- Road lighting

- Raised turret (170 cm)

Each of the sprayers can be equipped depending on the individual needs of the customer.

Technical Specifications

Components

- Hydraulic boom lifting

- Mechanical stabilization

- Hydraulic stabilization

- 4-section Polish distributor

- ARAG 5-section constant pressure distributor

- Open / close electrical panel (for ARAG constant pressure valve)

- Solenoid valves (electric valve control from the tractor)

- Computer ARAG BRAVO 180S

- Computer ARAG BRAVO 300S

- Computer ARAG BRAVO 400S (Build in GPS navigation)

- Pump MONSUN PPM100

- Pump UDOR

- Single luminaire type VK

- 3-position fixture (head)

- Road lighting

- Pressure regulation

- Control of 5 liquid sections plus main valve

- Cable for connecting sections, equipped with a bayonet connector with a slider

- Supply voltage 12 Vdc

- LED indicators

- * Can be equipped with foam tags

Bravo 180S is a compact and inexpensive computer, but extremely effective and accurate, able to meet the requirements of users of agricultural machinery of medium and large dimensions.

Technical characteristics:

- Built-in tank level indicator

- Expandable to 7 liquid sections

- Connections to GPS and main remote control

- USB port for data transfer and program update

- Automatic closing of the main valve when connected to Bravo 400S / Delta80

- Automatic blocking of spraying below the set minimum speed so that nozzles can work continuously inside their application zone

- Visual and audible alarms

- Multilingual software with the ability to set different measurement units (l / ha, GPA, GPK, l / 100m, etc ..)

- Displayed data: dosing, speed, pressure, flow rate, split quantity, tank level, area treated, treatment duration, mileage

The Bravo 300S is a medium to high range computer capable of managing all the functions of the weeding machine. The remote control unit facilitates the connection between the tractor and the machine.

Technical characteristics:

- Graphic indicator for tank level

- Automatic section closure when connected to Bravo 400S / Delta80

- Registration to SD or transfer via serial port of position and operation data

- Automatic locking of the spraying below the minimum set pressure so that the nozzles always work within their operating range

- Visual and audible malfunction alerts

- Built-in reader for Secure Digital (SD) cards

- External input to control the main valve

- RCU control unit

- RS232 serial port for connection to GPS

- Inputs for signals: performance. speed, pressure, capacity, tank level, rev counters

- Outputs for controlling 7 boom sections (13 in sequential version), regulation valve and main valve and foam marker

- Outputs for control of 9 hydraulic functions and a drain valve

- 240 × 64 pixels backlit graphic display

Monitor for electronic regulation of capacitive distribution of spraying with large 5.7 ″ color display and integrated GPS navigator.

Automatic closing control of up to 13 water sections.

Automatically selects the correct nozzle configuration so that:

- the spraying pressure was always within the operating data set for each individual nozzle;

- out of several nozzle configurations the one with the working pressure closest to the working range of the nozzle has been used;

- the number of nozzle changes has been reduced to a minimum.

Variable application by selecting more nozzles with great variation in dosing, which reduces costs and environmental impact.

The main operating visualization can simultaneously display information and a picture for easy driving and spraying data.

The user can select a combination of several pieces of information useful while driving by pressing a separate button.

Object visualizations displaying:

- images from two optional external cameras, spraying / guidance operating data, information and alarms, variable rate map;

- main driving functions: calculating the acreage and perimeter of the field, marking various types of points and driving the vehicle back.

2 USB ports and 1 SD card for data transfer and software upgrades.